Use cases

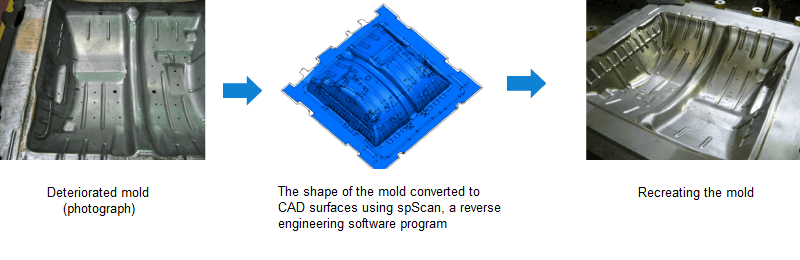

Restoring Deteriorated Molds

Here is an example of spScan reverse engineering utilized to restore molds that have deteriorated from long years of use.

Creating 3D data for products that have only 2D drawings

If a press mold has been used for a long time to produce the same part, even if 2D design drawings for the mold exist, no 3D CAD data exists for the current mold because it was not designed using 3D CAD software.

In order to use current CAD, CAE, or CAM software to make parts design change or repair molds, the shape of the current mold needs to be converted to 3D CAD data.

Problems when using a CAD system for reverse engineering

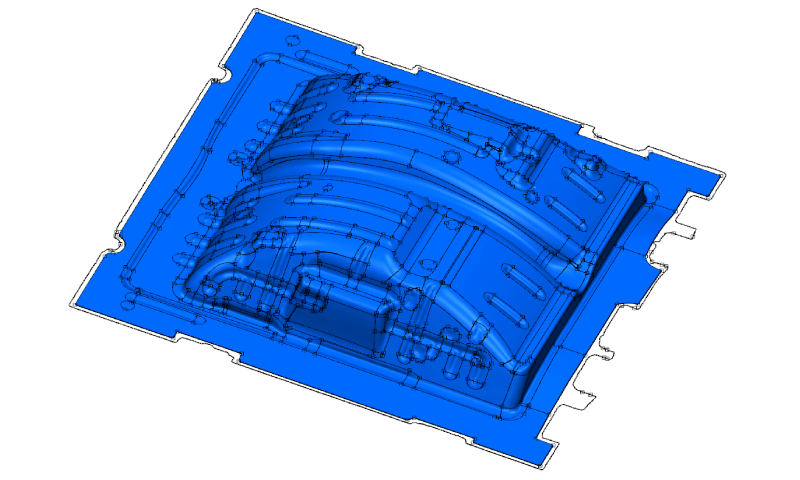

Data obtained using a no-contact measuring device to measure the current mold was imported into 3D CAD software, and the mold shape was converted to CAD surfaces (reverse engineered), but the following problems occurred.

- The measurement data (point cloud data) volume was so large that not all the point cloud data could be imported into the CAD under certain circumstances.

Before using the CAD software, we needed to carry out pre-processing on the point cloud data, such as thin-out, dividing, or creating sectional curves from the point cloud data. - Using CAD software to create the spline surfaces imposed a significant workload.

- It was difficult to guarantee the amount of error between the die shape created with CAD software and the actual measurement data.

Using tools specifically intended for reverse engineering reduced the CAD surface conversion man-hours to one fifth.

spScan is a software program specifically for reverse engineering.

Utilizing no-contact measurement data obtained by measuring the mold currently in use, it can carry out reverse engineering that is faithful to the actual object by checking for errors with the point cloud data CAD surface conversion is being performed.

The man-hours required in reverse engineering are greatly reduced by the use of tools specifically intended for reverse engineering. (CAD surface conversion man-hours are reduced to one fifth.)

Using the reverse engineering data, we were able to eliminate obstacles to mass production of the current product by restoring a deteriorated mold to create a new mold.