Use cases

Supportive Features for Design and Manufacturing Tasks (Plastic Manufacturer)

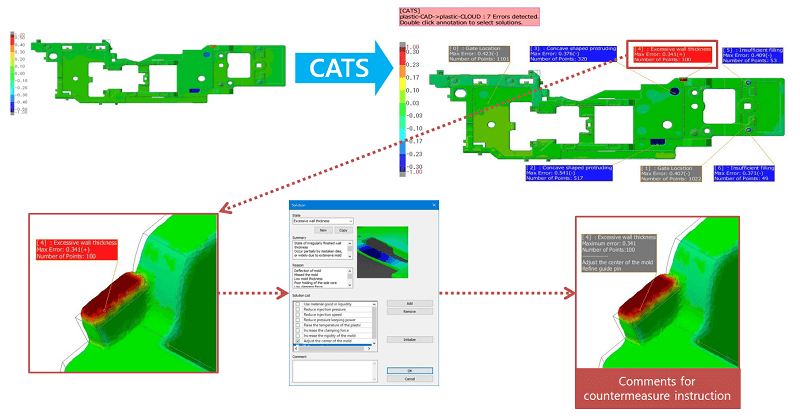

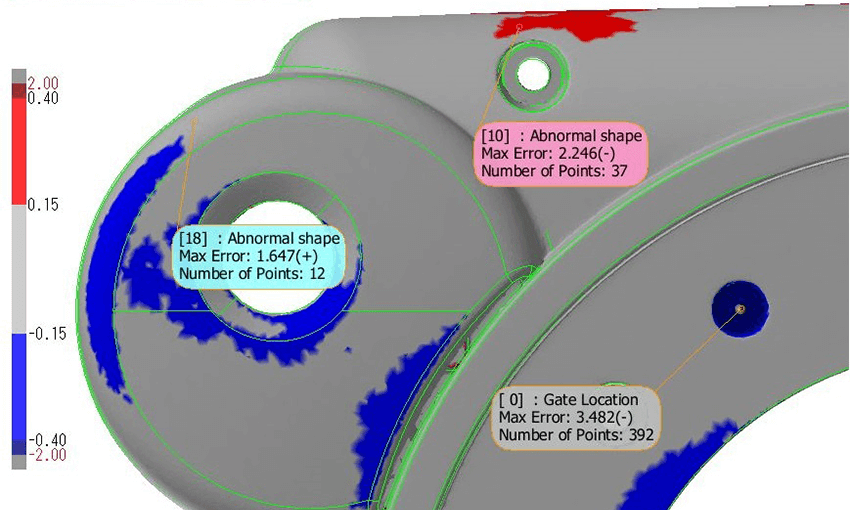

You can easily check defective areas and phenomena through shape inspection (error color mapping), but simply displaying the locations of defects does not prevent the occurrence of human error, including checking oversights and judgment errors.

Not only does spGauge detect all defective areas that deviate from the CAD data without omission and display the number of the defective areas, but it also displays phenomena and its causes inferred from the characteristics of the CAD data shapes in the form of annotations.

From the detection of the defect phenomena in plastic products to countermeasure instruction

CATS_Mold, an optional feature for spGauge, has a tool for displaying phenomena annotations at defective areas according to results of shape inspection. The countermeasure to be taken depends on the phenomenon, which includes sink marks, underfilling, knockout pin tracing errors, external shape dimension errors, warp, and torsion.

There is a variety of countermeasures that include changing the design of mechanical components such as mold gate locations and cooling conduits, and changing the molding conditions such as the filling temperature in accompany with shrinkage. You can build a database for countermeasure instructions specific to each user to provide the instructions in response to phenomena at defective areas.