Use cases

ClassNK-PEERLESS realizes work during the phase of measuring the site and construction planning!

Kanden Plant Corporation is engaged in a wide range of plant engineering projects, including construction and maintenance of thermal and nuclear power generation facilities.

Their main projects include installing the thermal and nuclear power generation facilities, the design and construction of piping and wiring, maintenance planning for mechanical/electrical/instrumentation equipment, trial operation and adjustment after disassembly/inspection/assembly, and periodic inspections.

Recently, the company has also expanded its business in the construction and maintenance of private power generation facilities, refurbishment of petrochemical and other facilities. The company also carries out integrated construction from design to installation in various plant facilities.

In this interview, we spoke to Mr. Morimura about the introduction of ClassNK-PEERLESS and its application to his work.

Challenges in speeding up the measuring process and construction planning

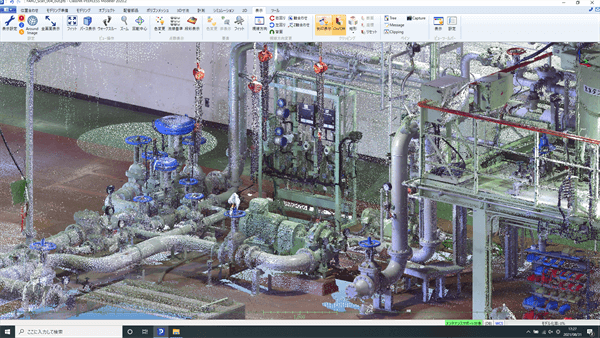

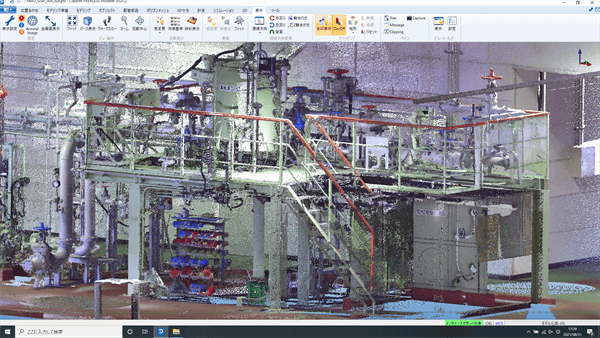

Measuring of pipes and other facilities were time-consuming because the first step was to measure with a tape measure, followed by sketching on paper, and forgetting to measure was also a problem. Therefore, it was necessary to reduce the time and effort required for measurement.

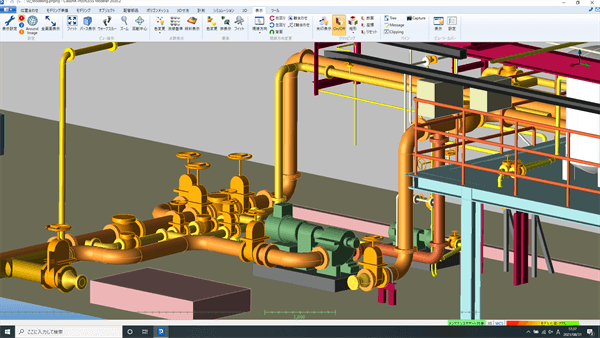

Moreover, there were increasing opportunities to study the planning of equipment loading and unloading routes and the layout of temporary structures in collaboration with the team on the site, so it was necessary to establish an efficient construction planning method.

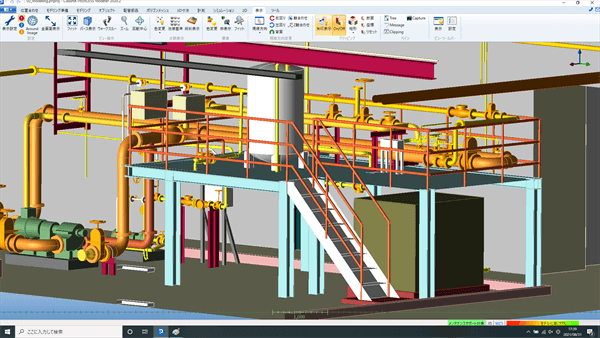

These situations brought us to introduce a 3D scanner which enables measuring of large areas in a brief time, and the 3D modeling software ClassNK-PEERLESS which enables simulation on a PC.

Simple operability and generous follow-up enabled a smooth introduction

Improvement of work efficiency

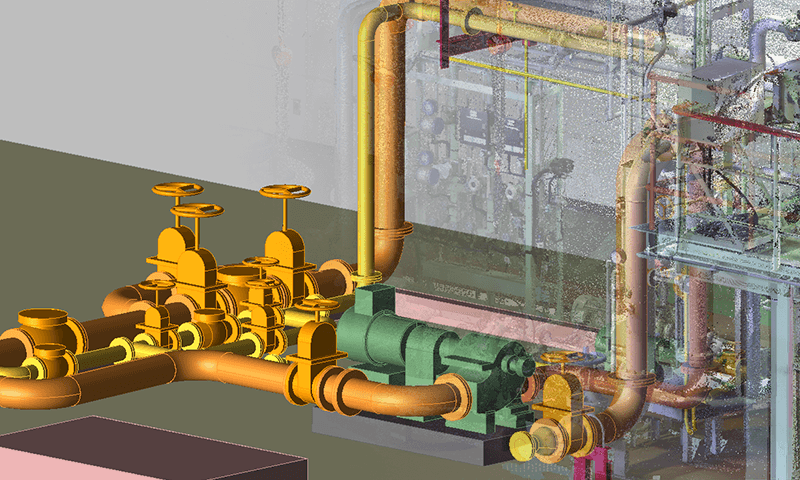

A 3D scanner and ClassNK-PEERLESS realized measuring and 3D modeling easily even when the target is a pipe at a high place which can’t be measured without a scaffold.

Additionally, we chose the floating license type which was convenient to be able to take turns using the license with the operators in remote locations.

Eliminating concerns when introducing a new system

Generally, when a new system is introduced, it is necessary to get used to its operation. So, we had high expectations for the ‘easy operability’ that is a feature of ClassNK-PEERLESS. In fact, the operation is so simple and once learned, work went very smoothly.

Furthermore, the follow-up support service after installation was also very attentive. When we encountered a problem with operation, Armonicos support team responded immediately, and we were able to work without too much delay.

Towards efficient operation of ClassNK-PEERLESS

Expanding the usage of point cloud data and 3D models

At present, we are in the introduction phase and exploring which kind of work will yield the best result.

First, we aim to accumulate experience with existing works, and solve new visible problems one by one, so that we can change “The work we wanted to do” into “The work we can do.” We will proceed by investigating what can be done with point cloud data and what can be done with 3D models.

Expect ongoing support and feature development to promote efficiency

Currently, we are increasing the number of bases across the nation. As construction work of plant facilities other than the power generation facilities is increasing and covers a wide range of subjects, we need to work efficiently on design and construction using 3D data. We expect Armonicos to continue to provide follow-up support and improve the functionality that contributes to the efficiency of our work.

- Detailed requests

- Development of an efficient and quick method for creating 3D models from point clouds.

- Improvement of modeling accuracy.

- Development of a function to add new piping data to modeled facility data easily.

- Development of a function to convert modeled data (such as building and pipes) into drawings.

User Profile

Kanden Plant Corporation

| Head office | 2-9-18 Honjo Higashi, Kita-ku, Osaka-shi, Osaka Prefecture |

| URL | https://www.kanden-plant.co.jp/ |

About how Kanden Plant Corporation got ClassNK-PEERLESS on track after the introduction phase, will be updated on this website in the new future!

tag : User case study