Use cases

Effortlessly Execute Measurement or Simulation

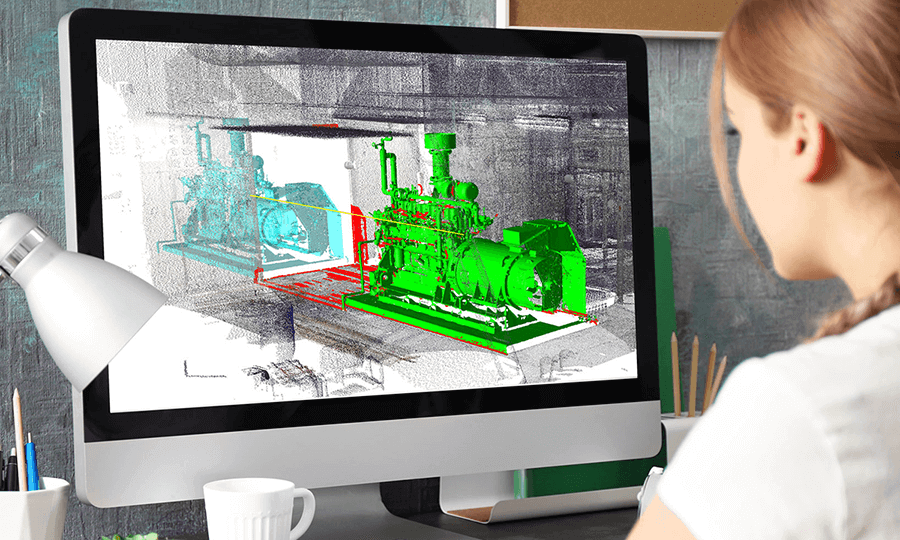

Modification work involves removing existing equipment and installing new machinery. ClassNK-PEERLESS is equipped with measurement functions as well as interference detection and collision checking functions.

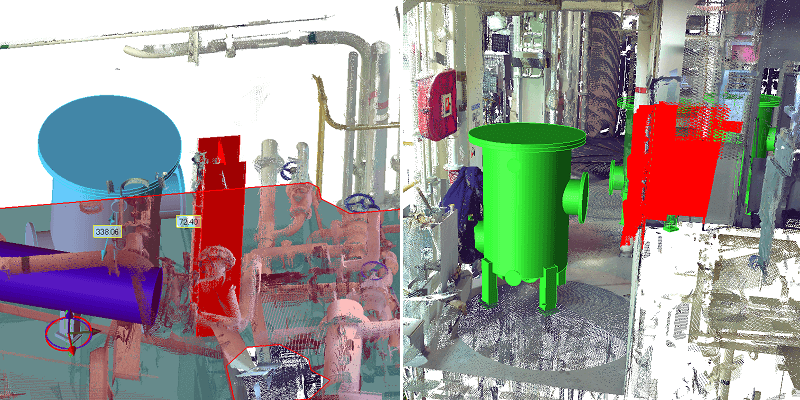

If you have a point cloud for the construction location, you can place equipment models within the point cloud to check for collisions with existing information, and you can examine machinery models and routes for carry-in and carry-out of the existing equipment.

Interference detection checking allows you to use dimension data to check for collisions with existing equipment and whether maintenance space has been secured. Collision checking allows you to check for collisions during carry-in and carry-out.

Usage

Shipbuilding: Examining the layout position of ballast water treatment system and SOx scrubbers as well as carry-in methods

Factories and plants: Examining the layout of new machinery as well as carry-in and carry-out methods

Issues

The following matters should be considered at planning stage for the machinery layout.

- Does the machinery interfere with existing equipment in near the planned layout position?

- Can maintenance space for existing equipment and machinery be secured?

- Is carry-in up to the planned layout position possible?

If examinations are performed based on past drawings or results of manual measurements at site, it may be difficult to guarantee a high level of accuracy.

- Measurement omissions

- Differences between drawings and actual equipment / low accuracy of manual measurements

For such reasons, it will be necessary to adjust at site during actual installation. If on-site adjustments are made, more construction time will be required, and, depending on the size of the machinery, more time will be required for cranes and other vehicles, leading to concerns about the issues of delivery time and cost.

Results

Understanding the positional relation between existing equipment and machinery

Use the interference detection checking function to check for collisions between existing equipment and machinery and for the maintenance space. This software lets you perform the following tasks.

- Automatically display dimension of the distance from nearby machinery.

- Verify point clouds where collisions occur.

Examining carry-in and carry-out routes

Use the collision checking function to visualize parts of the machinery having a collision with existing equipment when it is moved. This software lets you perform the following tasks.

- It highlights point clouds and nearby machinery having a collision when moved

- It saves the status of machinery moved as a video file.

tag : Simulation